Features & Uses

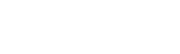

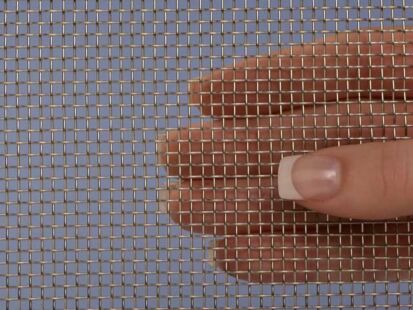

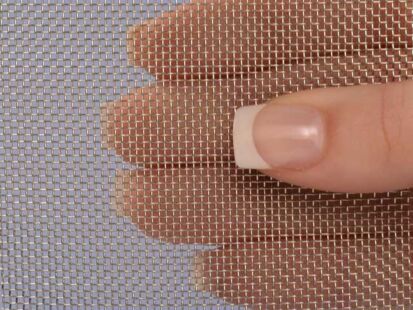

Monel 400® is woven into an extremely corrosion resistant wire mesh material. This is a plain square weave (over one, under one). Weaving meets ANSI/AWCI - 01 -1992 and ASTM E 2016-11 and RRW 360.

Monel 400 Wire Mesh® is resistant to:

-

High temperatures

-

Corrosion

-

Steam

-

Seawater

-

Pressure cracking

-

Oxidation

-

Sulfuric acid

-

Hydrochloric acid

-

Hydrofluoric acid

-

Alkali

-

Fluoride

-

Static

-

Harsh cleaning solvents

-

Frying oil

The material can be used in chemical production, electrical engineering, waste incineration, heat exchange, petroleum refining, welding, and many other commercial products and processes.

Choosing Your Wire Mesh Material

Monel Mesh® is made up of 67 percent nickel, 28 percent copper, and 5 percent other metal alloys. With a certified chemical composition of ASTM B164-03, it meets the standard specification for nickel-copper alloy wires.

Monel Mesh® Weave Types & Sizing Options

Monel Mesh® consists of a plain over-under square weave designed with superior mechanical strength and durability. As a result, it is highly resistant in many extreme commercial and industrial environments. The weave is considered to have precise and long-lasting filtration capabilities. Monel Wire Mesh meets the ASTM E2016-15 standard specification for industrial woven wire cloth.

Monel 400 Wire Mesh® comes in a range of sizes. With a 2 mesh size, two wires will run in each direction per square inch, which creates relatively large openings about the size of a pencil. 16 mesh will have 16 wires running in each direction per square inch and is commonly used for medium filtration needs such as window and door screens. 80 mesh consists of 80 wires running in each direction per square inch with openings about the size of a strand of hair. The finer the mesh, the easier it is to cut. With a fine mesh of size 60 or higher, the material can be cut with heavy-duty scissors, but the heavier sizing will require industrial shears or tin snips. Monel Wire Mesh® discs from TWP Inc. come in 500 standard-width diameters, but we also offer specialty sizes.

Monel Wire Mesh® from TWP Inc.

TWP Inc. is dedicated to offering quality materials that can be used for a wide range of residential and commercial applications. The unique strength of Monel 400 Wire Mesh® makes it stand out amongst other filtration materials. It holds up with high performance in a variety of demanding industrial operations. It is used in pumps, shafts, valves, and heat exchangers in marine, chemical, agricultural, and aerospace environments.

Since 1969, TWP Inc. has been the number one wire mesh choice for industry, science, and home. We provide quality mesh products as well as fabrication and laser cutting services. Additionally, mesh sample kits can be ordered online.

Get in touch with an expert from the TWP Inc. team to learn more about the products we offer and discuss your wire mesh needs.