Features & Uses

When raw petroleum and crude oil are extracted from the ground, they typically contain a variety of contaminants. Small rocks, wood fragments, sand, dirt, and other particles must be removed through the process of oil refinement.

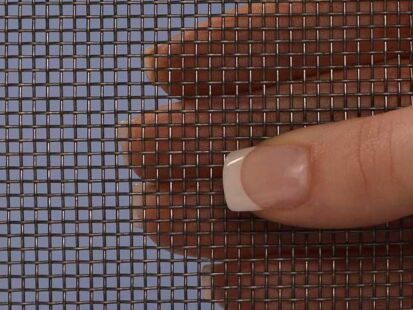

Wire mesh filters used to strain oil often come in round discs. However, some applications call for larger sheets or other shapes. By removing contaminants from oil, a mesh strainer can help extend the lifespan of many types of machinery.

This type of wire mesh is intended to filter and refine various oils and fuels, including:

Pharmaceutical, medical, automotive, agricultural, marine, HVAC, bioscience, aviation, clothing production, plastic production, food production, chemical engineering, and a multitude of other industries utilize a form of oil filtration.

Materials, Weaves, & Sizes

When it comes to oil filtration wire mesh, the materials most commonly used are plain stainless steel and brass.

Stainless steel: Plain steel mesh is often relied on in the refining process to remove impurities from crude oils. The material stands out for its versatility, durability, and resistance to corrosion. All stainless steel mesh products from TWP Inc. are compliant with RoHS (Restriction of Hazardous Substances Directive).

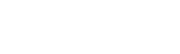

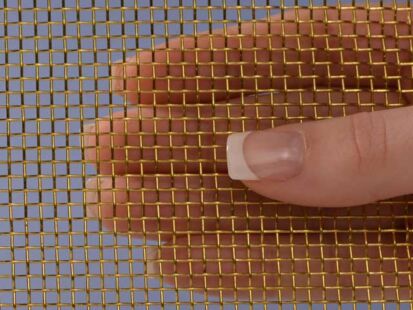

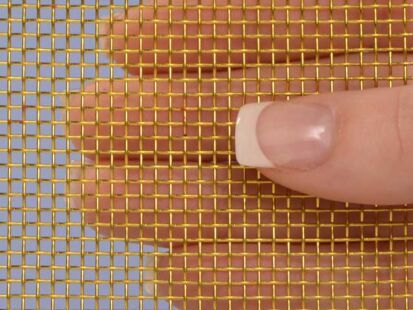

Brass: Brass oil strainer wire mesh is known for its tensile strength and resistance to abrasion. Made up of roughly two parts copper and one part zinc, brass is relatively flexible. Although it corrodes in some environments, it’s much stronger than copper mesh.

The strength, flow rate, and aperture are essential components that make up the proper weave for oil filtration. While oil filters require a semi-fine fabrication, wire mesh weaves should be larger than 0.005 inches.

When selecting wire mesh for oil filters and strainers, be sure to consider:

-

The amount of oil to be filtered and the volume of solids to be removed

-

Whether filtration will occur continuously or in batches

-

Whether the discharge should be a dry solid, wet solid, or concentrated slurry

When you browse our inventory, you’ll find a wide range of wire diameters, opening sizes, widths, and mesh weave sizes. Choose from 8, 10, 12, 14, 16, 18, 20, 30, 40, or 50 squares per linear inch.

Mesh for Oil Filters & Strainers from TWP Inc.

Our mesh for oil strainers comes in over 500 different disc sizes as well as large rolls and sheets by the foot. We also offer bulk orders in addition to custom sizes and quantities. Our expert in-house services include disc cutting, roll slitting, and laser cutting. No matter the size, shape, or quantity you require, we will meet the needs for your unique application.

Order your wire mesh filters today, or request a quote on a custom order.