Features & Uses

TWP Inc. carries high-quality wire mesh filter screen materials suitable for hydraulic filters. While hydraulic fluids move through a relatively contained system, using filters is still crucial. Hydraulics are used in heavy-duty industrial machinery. In motion, the machinery can create a buildup of small metal particles, which must be removed through a wire mesh filter. In addition to metal filings, a screen will expel internal contaminants such as abraded rubber and plastic while keeping dirt, debris, and other external pollutants out of the hydraulic circuit. Unfiltered hydraulic fluid will cause leakage, and ultimately, deficient machinery.

Features of Wire Mesh Hydraulic Filters

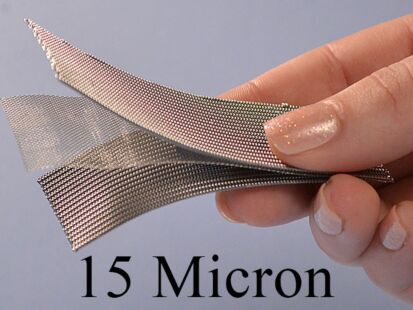

The non-fraying wire mesh filter screens from TWP Inc. are ultrasonically cleaned using ultrasound water and agitating solvents. Upon video inspection and XRF (X-ray fluorescence) alloy analysis, the finished product is certified based on its physical and chemical attributes. This type of wire mesh comes in a standard mill finish and is resistant to salt, acids, chemicals, seawater, and other corrosive substances.

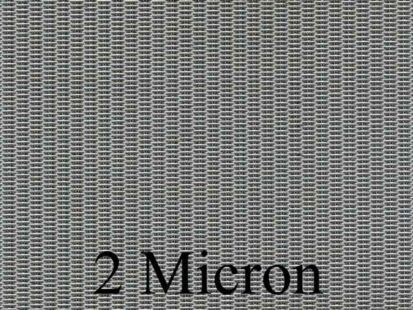

Woven screen filters are sometimes used to remove water and air from hydraulics, but they are primarily used to filter out microscopic contaminants and other tiny particles from fluids. The material can be used for various industrial projects as well as commercial, agricultural, medical, pharmaceutical, laboratory, and marine filtration systems. Examples include breather vents, precision auto parts, diffusers, semiconductors, vents, purification equipment, and food-processing machinery.

Materials, Weave Types, & Sizing Options

When you browse our hydraulic filter products, you'll find materials with varying mesh weaves and size options. Hydraulic filters are made from different forms of stainless steel, including the basic stainless Alloy Type 304 (T-304), Type 316 (T-316), and Type 316L (T-316L). When it comes to woven mesh screens, stainless steel is the most popular metal. In addition to being the strongest and most commonly used hydraulic filter mesh, T-304 is typically the most budget-friendly. However, T-316 offers the most corrosion-resistance.

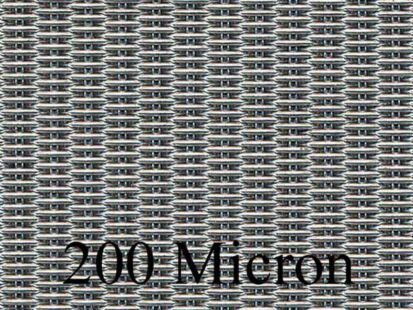

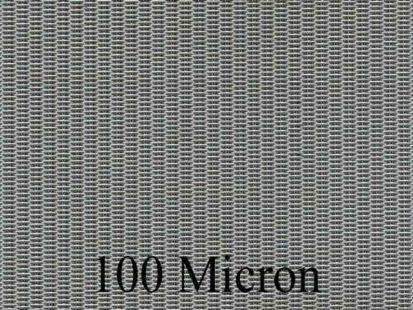

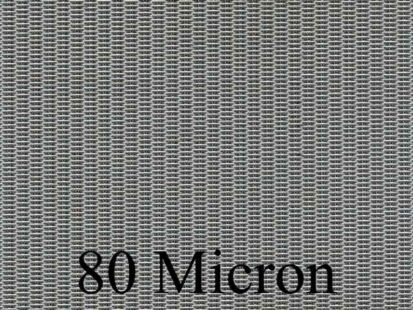

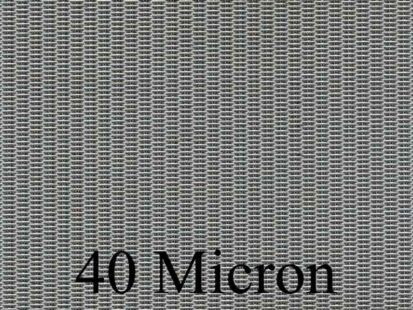

Weave types include the option of 1-ply, 2-ply, 3-ply, 4-ply, or 5-ply as well as plain weave or dutch weave with various opening sizes. Choose from full rolls, square-foot pieces, swatches, and mesh discs with either standard or special diameter sizing.

Hydraulic Filters & Discs from TWP Inc.

A proper filter is essential to the ongoing function and efficiency of hydraulic-powered machinery. The type of filter needed for a hydraulic system depends on what contaminants will be encountered both inside and outside the machinery. Our durable and uniform hydraulic filters and discs come in a wide range of specifications.

Most stainless steel meshes can be easily cut with scissors, while others will require heavy-duty shears or tin snips. With wire diameters over .047 inches, a specialized cutting tool is necessary. We offer custom sizing and expert laser cutting and slitting services as well as a substantial selection of pre-cut mesh products. Shop our collection of hydraulic filters online, or contact one of our experts to get a free quote on a custom order.