In the age of smartphones, voice assistants, and 3D printing, the mining industry is still alive and well. In fact, we wouldn’t have these technologies without materials which have been extracted from the earth — not to mention the electricity that powers them.

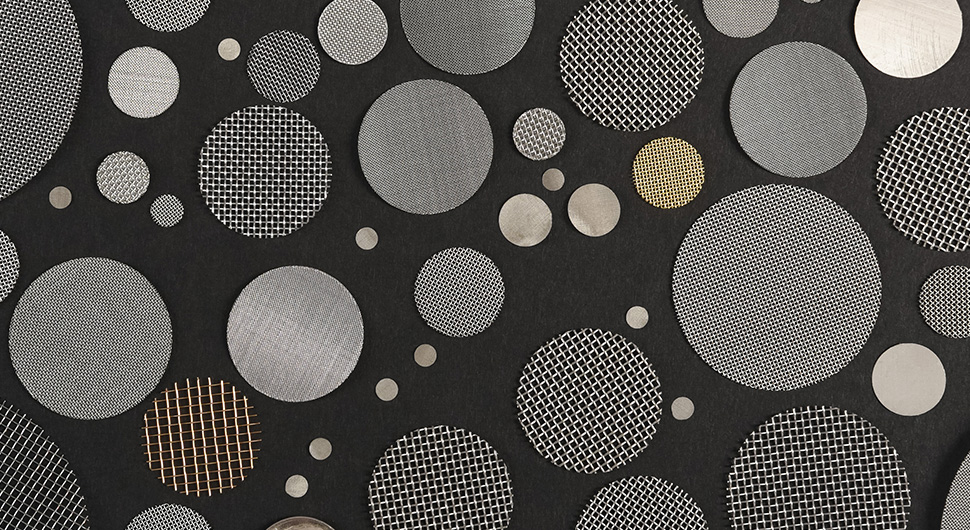

The mining industry involves two sectors: the search for geological resources and the actual mining of these substances. Wire mesh filter discs, which are primarily used for filtration purposes, play a critical role in mining. They’re used for both extracting geological elements from the earth and processing them at a later time.

There are many industries reliant on mining, including:

- Aerospace

- Automotive

- Ecological testing

- Food production

- Jewelry making

- Manufacturing

- Metal purification

The Role of Filter Discs in the Mining Industry

As mentioned above, the primary use of wire mesh discs in the mining industry is filtration. That being said, the type of filtration and its specific purpose varies depending on the application.

Contamination Prevention

Wire mesh screen discs are often used to prevent mined substances from becoming contaminated. The metal screens are designed to filter out twigs, grass, rocks, metal slag, debris, and unneeded minerals.

Screening Media

Screening media is a material that separates substances into grades. Stainless steel wire mesh discs are used in mines as screening media for sizing extracted ores, separating, shaking, washing, and cleaning.

Mine Sieving

Mesh discs are also used for mine sieving, which involves separating particles based on size. Most often, wire mesh sieve discs or plates remove coarse particles from fine materials.

When it comes to mining, metal mesh can filter materials through vibration as well as in a stationary state. Of course, preventing contamination, screening media, and mine sieving aren’t the only types of filtration utilized in the mining industry. Wire mesh (whether in discs, sheets, or other shapes) plays a key role in numerous mineral extraction and processing applications.

Essential Features

Mesh discs, which are sometimes called filter discs or pack screens, are manufactured out of woven or sintered hardware cloth. Heavy-duty, high-performance metal mesh materials are crucial in mining as well as in a number of other industries.

One of the most essential features is resistance to abrasion. This is particularly important for filtering earth-sourced materials, which tend to be highly abrasive. Abrasive-resistant stainless steel wire mesh is known for its durability and resistance to corrosion. It holds up for many years under harsh conditions in a wide range of environments.

Wire Mesh Materials & Filter Discs from TWP Inc.

TWP Inc. carries a massive inventory of industrial-quality wire mesh filter discs that can be used for myriad applications. We offer both single- and multi-layer metal mesh discs with the option of welded, sintered, or covered edges.

While you can get discs in numerous materials, stainless steel is the most popular choice. With that said, TWP Inc. has several varieties of stainless steel to choose from, including galvanized, micronic, T-304 (Alloy Type 304), and T-316 (Alloy Type 316).

The high-tensile wire mesh discs from TWP Inc. can be used in:

- A broad variety of filtration systems

- Pipes and tubes

- Inline filter ducts

- Other tools, devices, machines, and appliances

In addition to discs, we carry a wide range of wire mesh products in a variety of shapes, sizes, thicknesses, weave types, and materials. Choose from versatile stainless steel or other mesh metals such as bronze, aluminum, copper, brass, and more. All wire mesh products from TWP Inc. are exceptionally sturdy, functional, and adaptable for endless uses.

TWP Inc. has been a leading industrial and residential mesh supplier since 1969. We’re proud to offer our premium products to customers all over the world. Aside from metal mesh materials, we provide personalized in-house services, including measuring, disc sizing, slitting, laser cutting, and cleaning.

Request a custom quote online or contact us today for more information.

Connect with us on LinkedIn to learn about what’s trending in your industry. We share the latest information on new applications, products, industrial materials, and more.