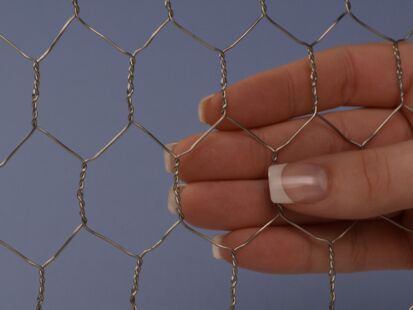

Wire mesh is durable enough for earthquake protection, versatile enough for any construction project, and strong enough for security purposes. From custom homes to commercial buildings, construction mesh, also known as construction cloth, is utilized in a variety of applications.

Wire Metal Mesh: Construction Applications

Construction cloth is engineered to withstand the demanding conditions of outdoor environments. Below are just a few of its uses:

Concrete Reinforcement: Screen mesh enhances the strength and stability of concrete structures.

Stucco and Plaster Support: Wire mesh provides a stable base for stucco and plaster applications.

Security Fencing: Construction screen mesh is used for job site security.

Erosion Control: Metal mesh prevents soil erosion and maintains stability on slopes and embankments.

Mesh Screens and Filters: Wire mesh acts as screens and filters in HVAC systems and drainage.

Safety Barriers: Wire mesh panels provide fall protection on elevated platforms.

Construction Mesh Varieties: Galvanized and Welded

Durable construction mesh varieties such as galvanized and welded offer robust solutions for various building and infrastructure projects and more.

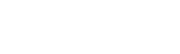

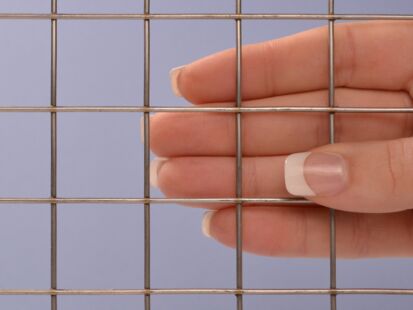

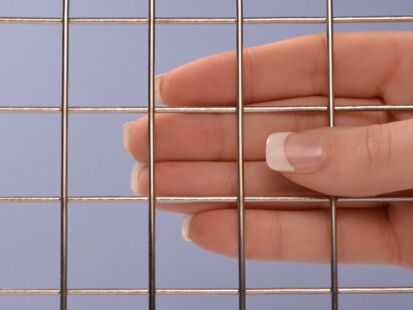

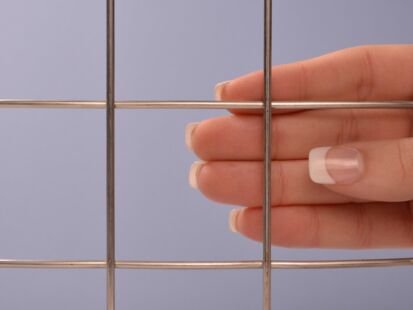

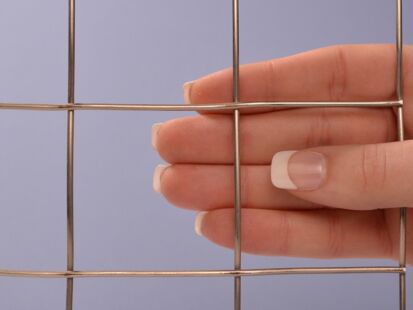

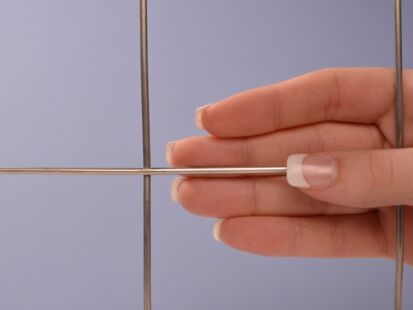

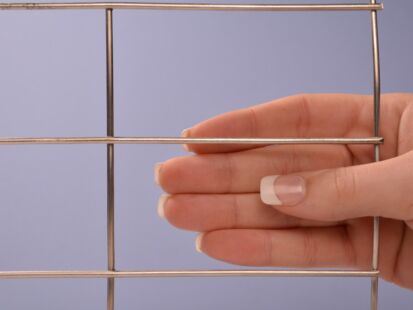

Welded Stainless Mesh

Using electricity and pressure, construction wire mesh may be welded at each intersection, adding durability for heavy-duty applications. Welded construction cloth is often the most economical option for construction.

Galvanized Wire Mesh

Dipped in zinc, galvanized wire mesh is extremely durable as well as corrosion-resistant. Galvanized wire mesh is often used to reinforce concrete in walls, foundations, and floors.

Supplier of Construction Cloth Screens, Rolls & Panels Since 1969

TWP Inc. offers customized services to suit your project requirements. Whether you need in-house laser cutting, cleaning, slitting, or more, reach out to request a quote or inquire further about our offerings, all delivered with expert craftsmanship and exceptional customer support.