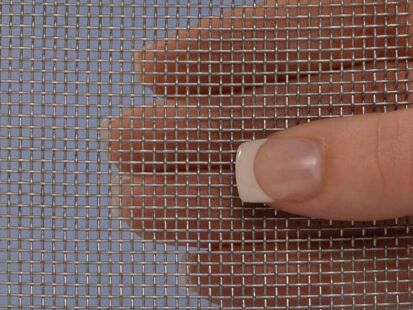

Mesh discs, alternatively referred to as pack screens or filter discs, are circular filters crafted from woven or sintered metal wire. These wire mesh discs play a pivotal role in various industries by facilitating separation, sorting, and sieving processes.

Industries That Use Wire Cloth Discs

- Medical and pharmaceutical

- Oil and gas

- Food and beverage

- Chemical

- Agricultural

- Water utility

- Mining

- Recycling

- Power and energy

Custom wire mesh filters may be designed to separate particles as small as one micron (one-thousandth of a millimeter). With the proper layers and metals, wire cloth discs can be refined to separate gasses from liquids.

Custom Wire Mesh Filter Specifications

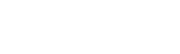

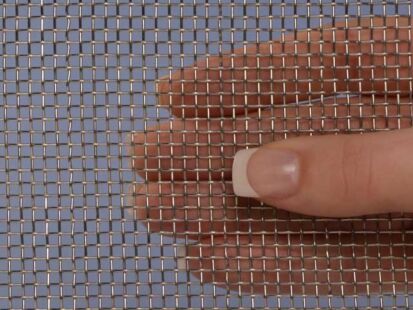

Filter discs can be constructed with either a single layer or multiple layers of wire mesh, sometimes featuring a metal frame covering the edges of the disc. Wire mesh filters can be woven or sintered, where the contact points of all wires are bonded through heat and pressure. Sintered filter discs are available in non-fraying single or multilayered mesh configurations, offering additional options in terms of metal type and weave pattern.

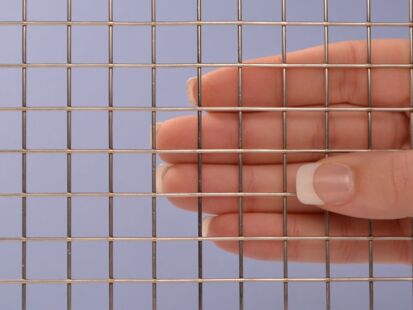

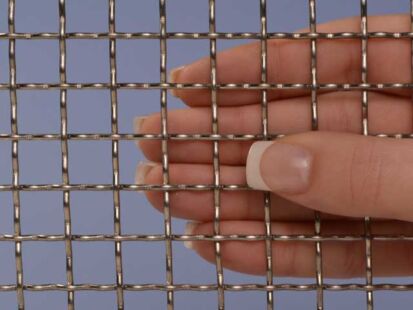

Weave Types for Filter Discs

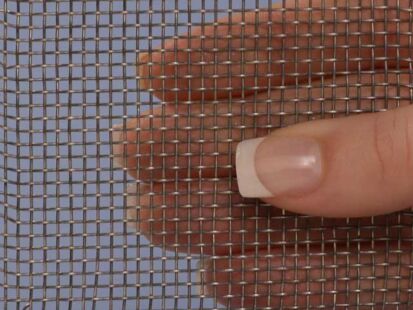

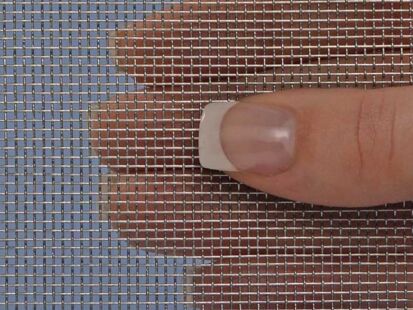

Intercrimp weave (Int.) is a pattern in which wires are crimped for added stability.

Plain Dutch Weave (PDW) is composed of a flexible, thin micronic mesh for efficient separation and sorting of solid particles.

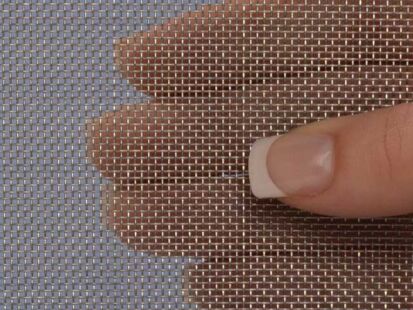

Twilled Dutch Weave (TDW) has a double layer of shute wires (which run the length of the roll of wire mesh) and no visible openings. As a result, the discs can support heavier loads, more pressure, and very fine filtration compared to plain Dutch.

Both PDW and TDW are typically used to filter fluids and vacuums as well as pressure filtration of gasses and liquids.

Surface & Finish Coatings for Filter Discs

Finish coatings provide an additional level of corrosion resistance.

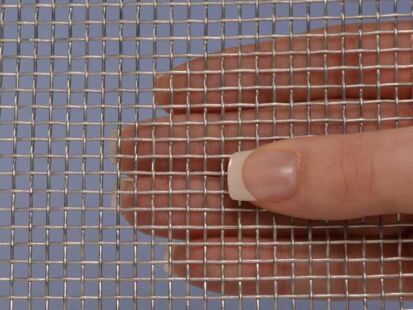

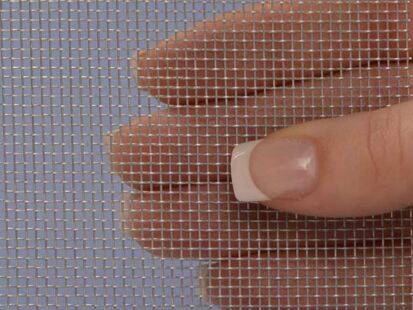

Mill Finish is somewhat rough to the touch. It is a bare finish with no coating.

Clear Lacquer Finish allows the metal material to shine through. Lacquer seals and protects the metal.

PTFE finish consists of a one-millimeter-thick coating of polytetrafluoroethylene (PTFE) to create a wire mesh disc that is hydrophobic, autoclavable, chemically inert, and durable, even under very high temperatures. PTFE coating is typically applied to stainless steel wire mesh discs.

Polyester coatings, available in dark green or black, are used to coat galvanized mesh filter discs.

Metal Wire Mesh Filter Discs: Stainless Steel & More

Since 1969, TWP Inc. has provided mesh discs and in-house laser cutting services to industrial and DIY clients across the nation. With our wide selection of materials, weaves, coatings, and sizing options, we’re dedicated to helping you find the wire cloth discs you need. Contact us to learn more about our products and services.